Solar Container Foldable Housing: The Future of Sustainable Living

Introduction: Why Solar Container and Foldable Homes Matter

Outline:

– Solar container homes: What they are, how they’re built, and where they shine.

– Foldable homes: How rapid-deploy structures work and what to expect day-to-day.

– Systems integration: Power, water, and waste for self-reliant living.

– Cost, codes, and logistics: What drives timelines and budgets.

– Roadmap and conclusion: Practical steps from idea to occupancy.

Housing is being reshaped by two forces that rarely arrive together: urgency and ingenuity. On one side, climate change is straining grids, pushing codes to favor higher efficiency, and nudging homeowners toward self-generation. On the other, affordability pressures and land scarcity are forcing smaller footprints and smarter materials. Solar container homes and foldable homes sit at this crossroads. They promise compact footprints, accelerated timelines, and measurable reductions in operational energy without requiring exotic technology. In many regions, buildings and construction account for roughly a third of energy-related emissions, while construction and demolition debris can exceed a quarter of landfill volume. Tight, well-planned small homes that repurpose steel or compress volume for transport can help ease both burdens.

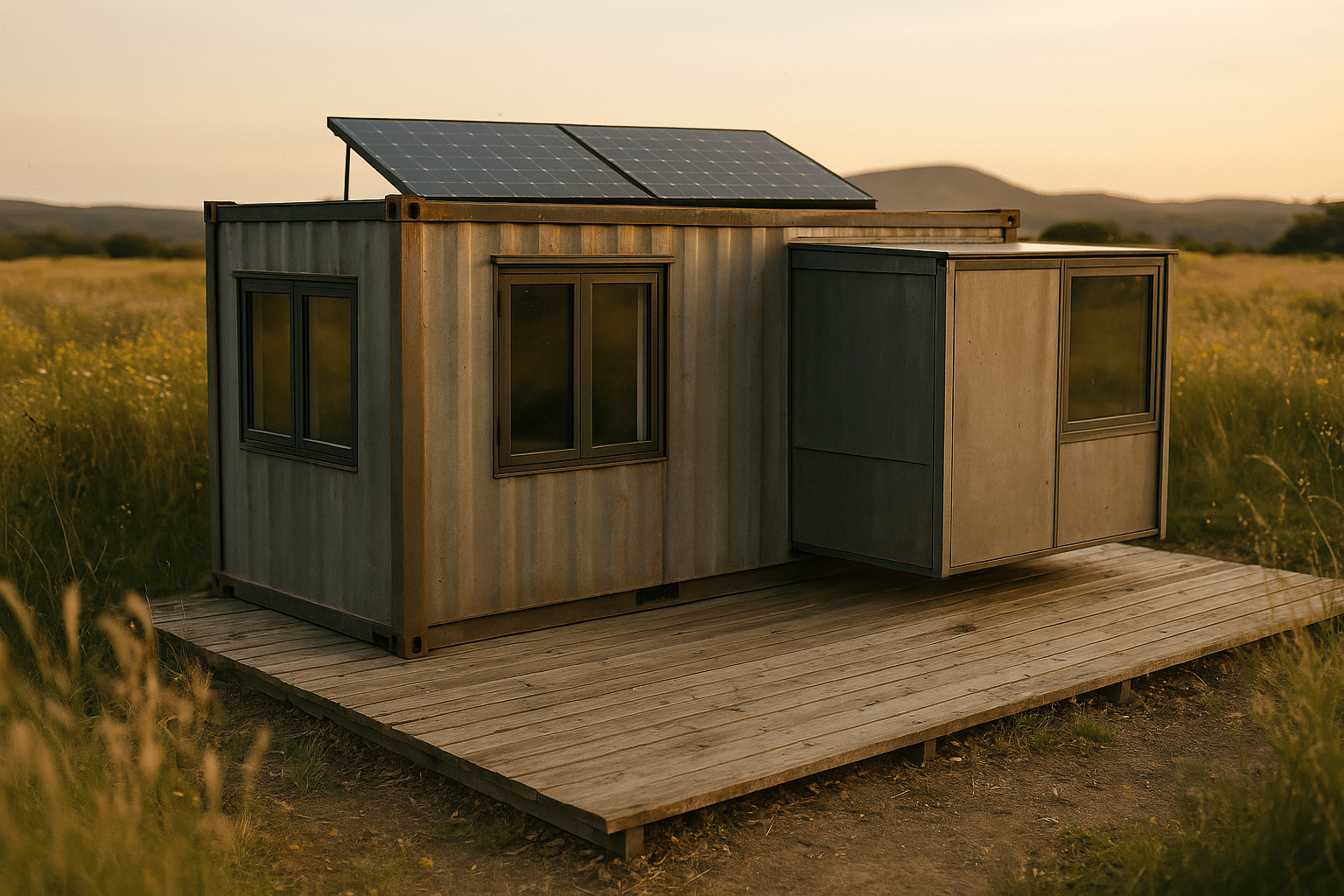

Solar container homes leverage the structural integrity of corrugated steel modules, turning a logistics workhorse into a durable shell. Foldable homes compress like a book, arriving as a compact bundle and unfolding into weather-tight rooms within days. Both options share a philosophy: move less air, insulate well, produce power locally, and keep systems simple enough to maintain without specialized crews. When paired with rooftop or ground-mounted solar and a modest battery, these homes can cover daily loads for lighting, refrigeration, and device charging, while efficient hot water and space conditioning keep comfort steady.

There’s no silver bullet in housing—site microclimate, local codes, and utility rules matter. Yet the pattern is clear: smaller, smarter, solar-ready structures are increasingly feasible. This article lays out how container and foldable homes are built, what they cost to operate, how to size the power system, how to manage water and waste, and where the trade-offs lie. By the end, you’ll have a grounded playbook to evaluate whether these approaches fit your needs and your site.

Solar Container Homes: Design, Energy, and Real-World Performance

A solar container home starts with a standardized steel box—commonly about 6.1 m long by 2.44 m wide for a 20-foot unit (~14.8 m²), or 12.2 m by 2.44 m for a 40-foot unit (~29.7 m²). The shell is strong, stackable, and transport-friendly, but it was never designed to be comfortable indoors. That means the build process focuses on three essentials: thermal control, moisture management, and smart openings. Without attentive detailing, the steel can bridge heat and cold straight through the wall, creating condensation and energy losses. The fix is a continuous insulation layer, an interior framing system that breaks thermal bridges, and careful air sealing at seams, doors, and windows.

Insulation often combines rigid boards outside (where allowed by local code), spray or batt insulation inside the frame, and a continuous vapor-smart membrane. Aim for wall assemblies near R-20 to R-30 (roughly 3.5–5.3 m²·K/W) depending on climate, with higher values for roofs, since solar gain can cook the box in summer. High-performance windows with low-e coatings reduce heat loss while maintaining daylight. Ventilation matters: a small heat-recovery unit can keep air fresh with minimal energy penalty, and properly sized trickle vents or operable windows can assist during mild seasons.

Energy-wise, households with efficient appliances often consume 8–12 kWh per day in small footprints. A 4–6 kW solar array paired with 10–20 kWh of storage commonly covers lighting, refrigeration, electronics, and intermittent cooking, while a heat pump handles space conditioning with a strong coefficient of performance. In sunny zones, annual production of a 5 kW array can exceed 6,000–8,000 kWh, enough to offset typical loads if usage is disciplined. Ground mounts are handy when the roof is small or shaded; adjustable tilt boosts winter yield.

Pros include ruggedness, relocatability, and material reuse. Common trade-offs include thermal bridging, narrow interior width, and the need for precise cutting and reinforcement around large windows. To decide if this path suits you, weigh the following:

– Advantages: High structural strength; modular expansion by adding units; straightforward transport; durable exterior that tolerates wind and impact.

– Trade-offs: Extra labor to insulate and air-seal; potential corrosion in marine climates without protective coatings; limited width that influences furniture and circulation; crane or forklift access during placement.

Real-world use cases include coastal cabins raised on piers to clear flood levels, desert studios with deep roof overhangs, and backyard suites tied to a main house via shared solar. A common pattern is pairing one living unit with a smaller service module containing bath, mechanicals, and storage. With a tight envelope and measured loads, operational costs can drop sharply, and the home gains resilience during grid interruptions. The key is not the container itself, but the building science layered onto it.

Foldable Homes: Speed, Structure, and Use Cases

Foldable homes compress for transport and unfold on site, delivering a weather-tight shell in days rather than weeks. Think of a book that opens into rooms: roof and wall panels hinge out, floors level, and integrated fasteners lock the geometry. The engineering relies on light but stiff skins—often steel, aluminum, or timber-based panels—paired with insulation cores that resist moisture and add rigidity. Joints are predesigned to align precisely, so a small crew with basic tools can assemble the shell quickly, then focus on finishes and services.

Deployment times vary by size and site, but a modest 35–50 m² unit commonly reaches dry-in within one to three days, with full fit-out ranging from several days to a few weeks. Because the package is compact, transport can be more efficient than moving a fully built module, saving fuel and simplifying access to remote sites. Many systems integrate conduits, window openings, and attachment points during manufacturing, which reduces errors and waste on site. When combined with screw piles or shallow concrete footings, foundations can be minimal, and the structure can be disassembled or relocated later if zoning allows.

Performance depends on detailing. Continuous insulation around hinges and seams is crucial to stop thermal leaks. A smart membrane and taped joints help control air and vapor flows. Roof overhangs, shading fins, and exterior blinds tame summer sun, while airtightness and heat-recovery ventilation stabilize winter comfort. Because many foldable designs maximize volume with minimal material, they can achieve favorable embodied carbon numbers compared to larger conventional builds, particularly when panels use bio-based or recycled content.

Where do foldable homes excel, and where do they need care?

– Strengths: Rapid setup; compact shipping; predictable factory tolerances; easy scaling by adding modules; suitable for temporary or semi-permanent use.

– Considerations: Hinge durability over years of movement and weather; careful flashing at fold lines; crane access on sloped or soft sites; code compliance for snow, wind, and seismic zones.

Common use cases include accessory dwellings, seasonal cabins, rural clinics, and interim housing during renovations. In disaster recovery, rapid deployment can restore privacy, sanitation, and cooling far sooner than traditional rebuilding. For long-term living, the same efficiency that enables quick setup also translates into low operational energy when paired with sensible solar and water systems. In short, foldable homes trade some absolute design freedom for speed, repeatability, and gentle operating costs.

Living Systems: Power, Water, Heat, and Comfort

A small home becomes truly sustainable when its systems cooperate rather than compete. Start with an energy budget. List your daily loads and right-size generation, storage, and backup accordingly. A typical efficient setup might include a 4–6 kW solar array, 10–20 kWh of lithium or similar storage, and a small inverter-charger. Pair that with induction cooking, an efficient fridge, LED lighting, a heat pump for space conditioning, and a heat pump or solar-assisted water heater. With this combination, many households can stay under 10 kWh per day while maintaining year-round comfort.

To sketch a simple daily load plan, consider:

– Lighting and devices: 0.8–1.5 kWh (LEDs, laptops, routers, chargers).

– Refrigeration: 0.8–1.2 kWh for an efficient unit sized to household needs.

– Cooking: 1–2 kWh depending on habits; induction is controllable and efficient.

– Space conditioning: 2–4 kWh in moderate climates; more in extremes, offset by shading and insulation.

– Hot water: 2–3 kWh with a heat pump water heater; lower if you integrate solar thermal or schedule uses.

– Miscellaneous (pumps, fans, laundry): 1–2 kWh with efficient appliances and load shifting.

Water and waste round out the sustainability picture. Rainwater harvesting scales with roof area and climate. As a rough rule of thumb, a 50 m² roof receiving 600 mm of annual rainfall could yield around 30,000 liters per year after losses—enough to cover efficient indoor use for one to two people if conserved. Pair storage with a first-flush diverter, sediment filtration, and a final filter at the tap. Greywater from sinks and showers can irrigate landscape in many jurisdictions when filtered and distributed subsurface, reducing potable demand. Where sewer hookups are distant, composting or urine-diverting toilets can cut blackwater volumes dramatically; always follow local plumbing codes.

Passive design amplifies every kilowatt. Orient glazing to capture winter sun and avoid direct summer gains. Deep overhangs, exterior shading, and deciduous plantings reduce cooling loads; a light-colored roof lowers peak temperatures. Operable windows placed high and low enable stack ventilation, drawing cool air in and exhausting warm air out. Inside, thermal mass—like a concrete slab or earthen wall—helps even out daily temperature swings. Finally, monitor use with simple meters and set “energy rituals”: laundry on sunny afternoons, hot water preheats before evening showers, and standby loads switched off at night. The result is a small home that sips resources without sacrificing comfort.

From Idea to Move-In: Planning, Permitting, and Long-Term Care

Turning a concept into keys-in-hand success starts with a reality check: your site, your rules, your budget. Before sketching floor plans, confirm zoning, setbacks, height limits, and whether movable or temporary structures qualify under local codes. Some areas treat container conversions as conventional dwellings once altered; others classify them as temporary structures. Foldable homes may be reviewed as modular or panelized construction. Either way, expect inspections for foundation, structural connections, electrical, plumbing, and fire safety. Engage a local professional early; it saves time later.

Next, build a budget that includes invisible line items. Beyond the shell and solar, costs often land here:

– Sitework: Survey, access road improvements, grading, and drainage.

– Foundation: Piers, screw piles, or slab, plus anchoring hardware.

– Utilities: Trenching, conduit, water storage, pumps, filtration, septic or alternative systems.

– Mechanical and electrical: Inverter, batteries, combiner boxes, disconnects, ventilation, and controls.

– Finishes and furniture: Moisture-resistant materials, compact fixtures, built-ins for narrow spaces.

– Permitting and professional fees: Plan reviews, structural stamps if required, and inspections.

Timelines vary by jurisdiction, but a common sequence is two to eight weeks for design and approvals, one to four weeks for site prep, and one to three weeks for assembly and commissioning—weather permitting. A container-based build leans on cutting and reinforcing openings, then insulating and finishing. A foldable build leans on precise unfolding, weatherproofing, and service hookups. In both paths, batch decisions early to prevent change orders that ripple through schedule and cost.

Maintenance is straightforward when systems are kept simple and accessible. Wash modules and check seals annually, clean gutters and rainwater screens quarterly, retighten fasteners after the first seasonal cycle, and test safety devices monthly. Solar arrays appreciate an occasional rinse in dusty climates, and batteries last longer when kept within recommended temperature ranges. Filters—air and water—need scheduled replacements to protect equipment and health.

Conclusion: Solar container homes and foldable homes give homeowners, small developers, and community groups a practical toolkit for resilient, lower-impact living. They favor conservation over excess, planning over improvisation, and measured comfort over waste. Choose the format that matches your site and lifestyle, size the systems to your real loads, and let passive design do quiet work in the background. With thoughtful execution, you can assemble a home quickly, live efficiently, and adapt as needs change—today and years down the road.