Understanding Whole House Generator Cost with Installation: A Comprehensive Guide for Homeowners in 2026

Introduction and Outline

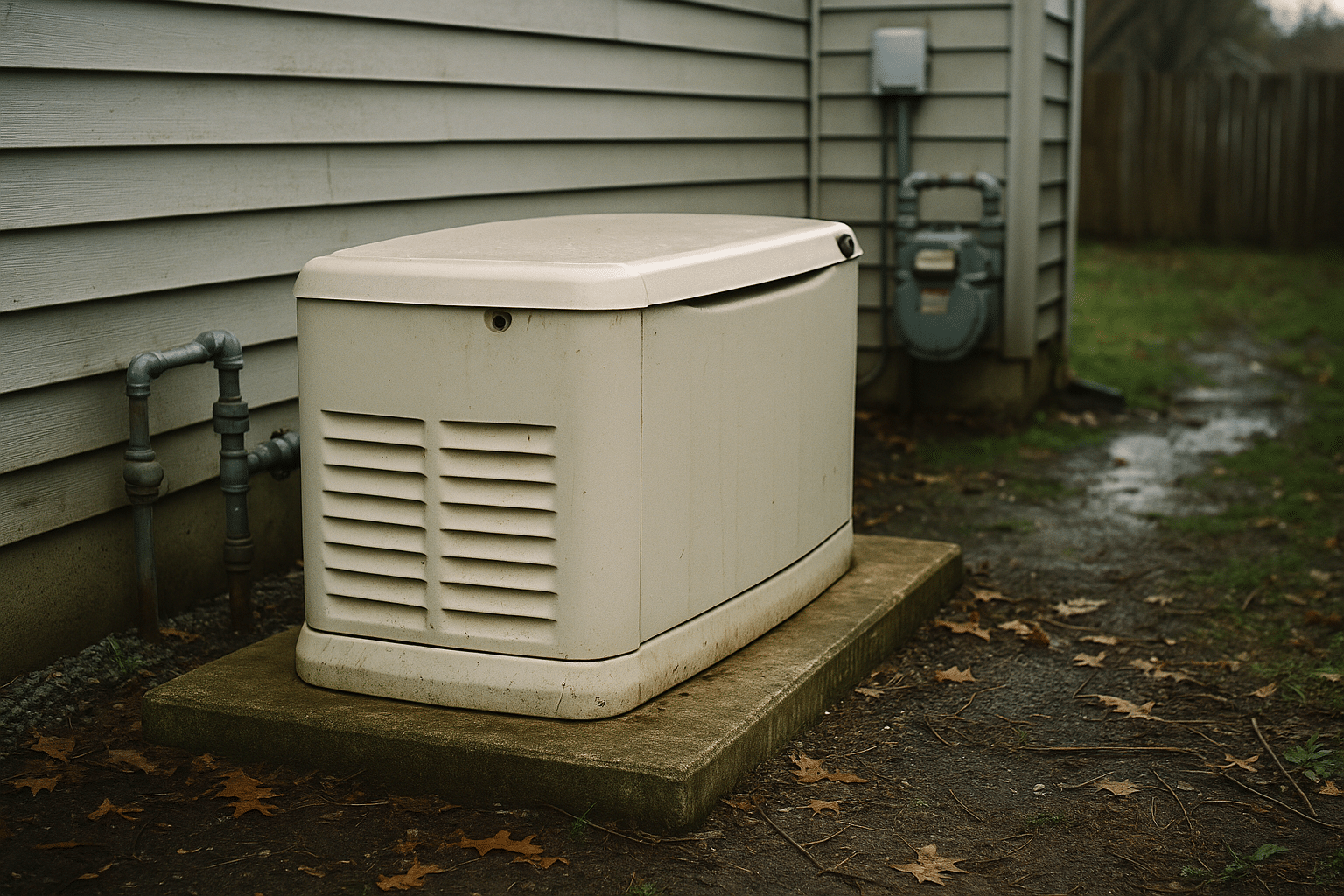

When the grid goes silent, a whole house generator can feel like a lighthouse on a foggy coast—steady, reassuring, and ready. But lighthouses are built with careful planning and real-world budgets, not guesswork. In 2026, installed costs for standby systems vary widely because every home has its own electrical needs, fuel options, and permitting rules. This guide is designed to remove the mystery. You’ll get practical numbers, context for those numbers, and a clear way to compare quotes, so you’re not choosing blind when the next storm rolls in.

Here’s how we’ll navigate the topic, and what you’ll take away from each stop:

– Overview of Whole House Generator Costs: We’ll map out typical price ranges for equipment and turnkey installation, from compact systems focused on essentials to larger units that can carry heavy loads. Expect realistic brackets, example scenarios, and notes on regional variability.

– Factors Influencing Whole House Generator Cost: We’ll unpack the levers that move quotes up or down—generator size, fuel type, site work, electrical service capacity, and local codes. You’ll see how a seemingly small detail, like trench distance or a meter upgrade, can change the total.

– Cost Breakdown: We’ll itemize line-by-line expenses—generator, transfer switch, pad, gas line or tank, wiring, permits, and commissioning. You’ll also see maintenance and fuel costs so you can plan beyond day one.

– Practical Comparisons and Case Examples: Woven throughout, we’ll compare typical homes and climates, showing how different load profiles influence equipment sizing and installation scope.

– Conclusion and Next Steps: We’ll close with a step-by-step approach for gathering quotes, right-sizing the system, and avoiding common pitfalls—without cutting corners on safety or compliance.

Think of this as your project brief. Read it once, mark what applies to your home, and you’ll be able to speak the same language as installers. That way, you can sort a sharp, well-regarded proposal from one that looks low at first blush but hides costly add-ons. And if you’re still weighing whether the investment makes sense, we’ll give you a framework to measure peace of mind against price, outage history, and the value of keeping your household or home office humming.

Overview of Whole House Generator Costs

Let’s zoom out and establish sensible ranges. For most single-family homes, a permanently installed whole house generator system—including equipment, transfer switch, pad, fuel and electrical connections, permits, and basic commissioning—typically lands between $7,000 and $22,000. That broad range reflects real variation in loads, locations, and labor. Complex projects serving larger homes or challenging sites can stretch to $25,000–$45,000. At the lower end are smaller, efficiently planned installs with short trench runs, straightforward panel tie-ins, and a readily available natural gas supply. At the upper end are larger generators, long trenching distances, rock or frozen ground, service upgrades, or the addition of a new propane tank or diesel day tank.

What counts as “whole house” varies. Some households target essential circuits—refrigeration, sump pump, heating controls, a few outlets—while others want near-normal living with central air, well pump, electric oven, and EV charging moderated by load management. The chosen scope directly affects generator size, which influences hardware cost and installation complexity. As a reference point:

– A modest, essentials-focused setup for a 1,600–2,200 sq ft home may total $7,000–$12,000 installed, especially with natural gas on site and no service upgrade.

– A mid-capacity system for a 2,200–3,000 sq ft home with central air commonly ranges $12,000–$20,000 depending on ducted HVAC tonnage and panel configuration.

– A higher-capacity system for 3,000+ sq ft, multiple HVAC zones, or heavy electric loads (pool equipment, well, large ovens) often lands $18,000–$35,000.

Fuel type matters too. Natural gas simplifies fueling where service is present, and consumption at half load for a 20 kW unit often falls in the 150–220 cubic feet per hour range, which translates into roughly a few dollars per hour depending on local gas pricing. Propane systems can be comparable in performance but require a tank; a 20 kW unit may use around 2–3 gallons per hour from half to full load, making runtime cost sensitive to propane pricing. Diesel units are known for robust torque and efficiency under heavy loads, with many using around 0.8–1.5 gallons per hour depending on size and load factor; they may add complexity for storage, pads, and sound attenuation.

Beyond first cost, budget for ownership: annual maintenance typically falls around $200–$500 for inspection, oil, filters, and testing. Some homeowners also choose cold-weather kits, remote monitoring, or load management modules. These add incremental upfront costs but can improve reliability, extend engine life, or right-size the generator by shedding nonessential loads during startup.

Factors Influencing Whole House Generator Cost

Generator sizing is the most visible driver. Installers estimate running and starting watts for critical appliances, then consider voltage drop, diversity (what realistically runs at once), and how aggressively to manage peak loads. Air conditioners, heat pumps, and well pumps have high inrush currents; without soft-starts or load-shedding, these can push you into a larger, more expensive unit. Thoughtful sequencing or adding a soft-start to a compressor may allow a smaller generator to perform seamlessly.

Fuel choice shapes both install and operating costs. Natural gas offers continuous supply where utility service exists, with no refilling logistics. Propane is flexible for rural sites but adds tank purchase or rental, pad or burial, regulator lines, and delivery scheduling. Diesel is attractive for heavy-duty applications and can be fuel-efficient under steady load, yet it often requires a more substantial pad, spill containment considerations, and sound mitigation. Your climate also matters: cold-weather starting equipment and enclosure insulation can be a wise upgrade in northern regions.

Site conditions can swing quotes significantly:

– Distance from generator to electrical service and gas source drives trenching, conduit, and labor.

– Soil and terrain (rock, clay, frost depth, retaining walls) affect excavation time and equipment needs.

– Clearances from windows, doors, vents, and property lines can force longer runs or a different pad location.

– Noise rules in dense neighborhoods may require upgraded enclosures or barriers.

Electrical infrastructure plays a starring role. A service upgrade (say, from 100A to 200A) can add material and labor, and some older panels complicate transfer switch placement. Decisions between a whole-house transfer switch, a service-entrance rated switch, or a load center with integrated transfer affect both hardware cost and installation approach. If your home relies on electric resistance heating or has multiple large appliances, you may benefit from load management modules that prioritize circuits and keep generator size reasonable.

Permitting and inspection requirements vary by jurisdiction. Expect line-item costs for electrical and fuel permits, plan review, meter upsizing if needed, and final inspections. Homes in hurricane-prone or wildfire-prone areas may require wind-rated anchoring, spark arrestors, or defensible space clearance, each adding material and labor. Finally, timing can influence pricing: during high-demand seasons after storms, labor availability tightens and lead times stretch. Planning off-peak can yield quicker scheduling and more competitive bids.

Cost Breakdown

While no two projects are identical, a transparent cost breakdown helps you compare apples to apples. Typical line items look like this:

– Generator head unit and enclosure: $3,000–$12,000 depending on capacity, enclosure grade, and sound attenuation.

– Automatic transfer switch or service-entrance switch: $400–$2,000, influenced by amperage and features.

– Concrete or composite pad, anchoring, and vibration isolation: $200–$1,200 depending on size and site prep.

– Fuel work: natural gas line extension or upsizing, regulators, pressure test; or propane tank purchase/placement, regulators, trenching, and permits—commonly $1,000–$6,000.

– Electrical labor and materials: conduit, wire, disconnects, bonding, panel work, labeling—often $1,500–$6,000.

– Site work and trenching: $300–$4,000, scaling with distance and soil conditions.

– Permits, inspections, and utility coordination: $100–$1,500.

– Startup, testing, and homeowner orientation: $200–$800.

– Optional extras: cold-weather kit ($150–$500), remote monitoring ($100–$400), sound fencing ($300–$2,000), extended maintenance plans (varies).

Putting it together, here are illustrative totals you can use as a sanity check:

– Essentials-focused install: $7,500–$12,500. A mid-size unit with an automatic transfer switch, short trench runs, existing natural gas service, and standard pad.

– Standard whole-house install: $12,000–$20,000. A larger unit covering HVAC, well pump, and kitchen circuits, modest trenching, minor panel rework, and fuel line extension.

– Complex or large-home install: $20,000–$35,000+. Large capacity unit, long trenching distances, difficult terrain, possible 200A/400A service considerations, new propane tank or diesel day tank, and sound abatement.

Don’t overlook operating and ownership costs. Annual maintenance typically runs $200–$500; plan for an oil change and inspection after any multi-day outage. Fuel expenses depend on load. A 20 kW unit might consume roughly 150–220 cubic feet of natural gas per hour at moderate load; using local utility rates, that could equate to a few dollars per hour. On propane, 2–3 gallons per hour means costs scale quickly with price per gallon. Diesel consumption varies with load but is often under 1.5 gallons per hour for mid-size residential units. If outages are frequent or long in your area, these running costs become an important part of your ROI calculation.

Two final budgeting tips: factor in a small contingency (5–10%) for surprises uncovered during installation—buried obstacles, panel limitations, or code updates—and make sure quotes explicitly include permits, startup testing, and homeowner training. Clarity now prevents extras later.

Conclusion: From Quote to Confident Purchase in 2026

By now, the path from curiosity to a reliable whole house generator should feel navigable. Costs vary because homes and priorities vary, but the structure of those costs is consistent: right-size the equipment, make safe and code-compliant fuel and electrical connections, and plan for long-term ownership. With that framework, you can evaluate proposals on substance rather than sticker shock, asking why a unit is sized a certain way, how loads will be managed, and what’s included from permits to final walkthrough.

Here’s a practical playbook for your next steps:

– Define your outage goals: essentials only, near-normal living, or somewhere in between.

– List major loads with starting and running watts, including HVAC tonnage and well pumps.

– Decide on fuel preferences based on availability, logistics, and running cost.

– Gather at least three itemized quotes that show equipment model class, transfer method, trench distances, pad details, permits, and commissioning steps.

– Ask about noise levels, cold-weather options, and load management strategies.

– Confirm maintenance schedule, warranty terms, and who handles warranty claims.

Timing matters too. If you can plan outside storm seasons, you’ll often see faster scheduling and sometimes more competitive labor rates. Where incentives or utility programs exist for demand response or efficiency upgrades, ask installers to flag them, as they can offset costs when bundled with panel improvements or load controls. Finally, remember that safety overrides shortcuts. Fuel lines, electrical interconnections, and code compliance are not DIY territory; choose licensed professionals and require a clear scope in writing.

For homeowners in 2026, a standby generator remains a well-regarded resilience upgrade. When the grid flickers, it protects essentials, preserves comfort, and keeps productivity from grinding to a halt. With a realistic budget, transparent quotes, and the right questions, you can invest confidently—without paying for capacity you don’t need or overlooking details that matter when the lights go out.