Exploring the Benefits and Considerations of Steel Roofing

Introduction and Outline: Why Steel Roofing Matters Now

Steel roofing has moved from niche to mainstream, and the reasons are practical as much as they are aesthetic. Across a range of climates, owners want resilient roofs that handle wind, fire, hail, and heat without constant upkeep. Builders and architects value a material that spans clean modern lines as easily as it mimics traditional shingles or tiles. And sustainability goals have pushed attention toward products with meaningful recycled content and a credible end-of-life path. Whether you manage a portfolio of properties or you’re planning a single reroof, understanding how steel performs—what it does well, where to be cautious, and how installation really works—can save time, money, and a few headaches down the road.

Before we dig into details, here is a simple roadmap for what follows. It gives you a quick way to skim and then zero in on what you need most.

– Five advantages that matter in day-to-day ownership: service life, weather performance, energy efficiency, sustainability, and maintenance/value.

– Five types you’ll actually see in the field: standing seam, corrugated/exposed-fastener panels, stamped shingles, steel tiles/shakes, and stainless or alloy-coated options for harsh settings.

– Installation process from planning to punch list: measuring, underlayment, flashing, panel layout, fastening, penetrations, and finishing details.

– Costs, upkeep, and decision criteria so you can balance looks, performance, and budget with fewer surprises.

Steel roofing’s relevance also tracks with the realities of today’s weather and building codes. Lightweight panels reduce structural loads relative to concrete or clay, which can simplify retrofits. Reflective finishes can trim summer heat gain, easing the strain on cooling systems. Fire performance is a strong point when assemblies are specified correctly, an important consideration in regions facing wildfire risk. Meanwhile, interlocking designs and longer panel lengths help control water intrusion during driving rain events. Taken together, these characteristics form a clear value proposition: a roof that looks refined, resists tough conditions, and offers predictable ownership over decades. In the pages that follow, we keep the focus on facts, with examples and practical comparisons so you can make decisions with confidence.

Five Advantages of Steel Roofing

1) Longevity and structural reliability. Properly specified steel roofs often deliver service lives measured in decades, commonly 40–70 years depending on environment, coating system, and maintenance. Their low weight—often in the range of 1 to 1.5 pounds per square foot for many profiles—reduces stress on framing and fasteners, which can be particularly helpful on older buildings or where snow load is a seasonal concern. Thermal movement is real for any metal, yet well-designed clips, fastener patterns, and expansion joints allow panels to move without loosening or oil canning when details are followed closely.

2) Weather and fire performance. Steel roofing is engineered to shed water quickly, resist uplift, and stand up to windborne debris better than many conventional materials. Panel systems are rated for specific wind speeds when assembled according to manufacturer details, and impact-resistant assemblies are available for hail-prone regions. With the correct underlayment and deck, steel can achieve a Class A fire rating, offering meaningful protection from embers and radiant heat. In coastal or industrial zones, selecting the appropriate coating or alloy is crucial to manage corrosion; that choice, more than anything, determines long-term durability in salty or chemically aggressive air.

3) Energy efficiency and comfort. Light-colored or reflective finishes can lower surface temperatures, reducing attic heat gain and, in some climates, trimming cooling energy use. While savings vary by house design and local weather, field studies often report cooling cost reductions on the order of 10–25% when reflective roofs are combined with adequate attic insulation and ventilation. Above-sheathing ventilation (an air gap beneath the panels) can further improve thermal performance by interrupting heat flow, especially on sun-exposed slopes.

4) Sustainability from start to finish. Many steel roofing products contain a significant proportion of recycled content, commonly cited in the 25–35% range. At end of life, panels and trims are fully recyclable, diverting material from landfills. In reroofs, some codes allow installation over a single existing layer, reducing tear-off waste and project time. Lightweight shipping and efficient panel coverage can also lower transportation and installation impacts.

5) Lower maintenance and steady value. Steel roofing does not absorb water, crack due to freeze-thaw cycles, or shed granules. Maintenance usually involves periodic inspections, clearing debris from valleys and gutters, and checking sealants or exposed fasteners on certain profiles. With consistent care, owners benefit from fewer emergency repairs and predictable budgeting. That durability and curb appeal can translate into strong resale interest, particularly where buyers value longevity, fire performance, and clean architectural lines.

Quick recap of owner-friendly advantages:

– Decade-spanning service life with modest upkeep.

– Strong resistance to wind, fire, and hail when assemblies are chosen wisely.

– Reflective finishes and ventilation strategies that support energy goals.

– Recycled content and full recyclability at end of life.

– Lightweight construction that eases retrofits and protects framing.

Five Types of Steel Roofing

Steel roofing is not one thing but a family of profiles and material options that serve different budgets, styles, and climates. Knowing the distinctions helps you match the roof to the building rather than forcing a one-size-fits-all choice.

1) Standing seam steel panels (concealed fasteners). Long, continuous panels with raised seams create a sleek, contemporary look and minimize exposed penetrations. Clips or concealed fasteners allow for thermal movement and clean lines. Pros include excellent weather shedding, compatibility with low to moderate pitches (within specified limits), and reduced maintenance because fasteners are protected. Trade-offs include higher upfront cost and a stronger dependence on skilled installation to keep seams straight, manage expansion, and integrate flashings without oil canning.

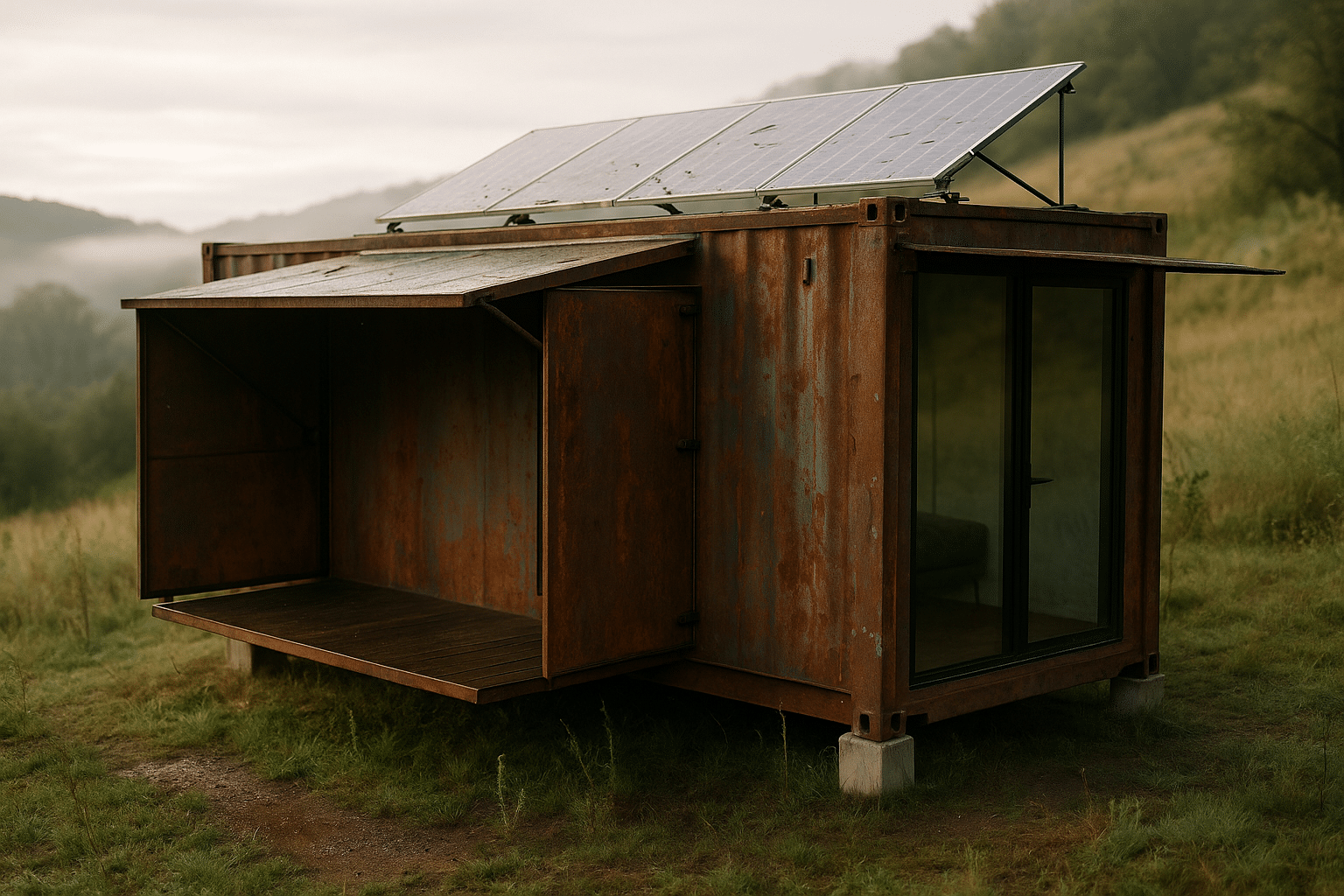

2) Corrugated or ribbed exposed-fastener panels. Recognizable by their waves or trapezoidal ribs, these panels are budget-friendly and quick to install. They suit barns, workshops, and cabins as well as certain residential designs with a rustic or industrial vibe. Advantages include lower material cost and rapid coverage per sheet. Considerations include more frequent fasteners, which means periodic checks for tightness and washer condition; careful screw placement is vital to avoid leaks. Over time, exposed fasteners may require retightening or replacement as gaskets age.

3) Stamped steel shingles. These interlocking panels mimic the scale and texture of traditional asphalt or slate-like shingles while offering the strength of steel. Because the units are small and interlock on all sides, they work well on complex roofs with dormers and valleys. Benefits include a familiar residential look, good wind resistance, and straightforward repairs—individual shingles can be replaced without disturbing large areas. Installation requires attention to starter courses and consistent fastening patterns to keep courses true.

4) Steel tiles and shakes. Formed panels replicate the look of clay tiles or wood shakes at a fraction of the weight, making them attractive for retrofits where structure won’t support heavy masonry. These profiles often include textured surfaces that break up reflections and add depth. They perform well on steeper pitches and pair nicely with architectural styles that favor shadow lines. Owners should confirm that underlayment and fastening patterns are appropriate for the profile’s uplift ratings and local code requirements.

5) Stainless and alloy-coated steel for harsh environments. In marine or industrial atmospheres, standard zinc-coated carbon steel can face accelerated corrosion. Upgrading to stainless steel or to carbon steel protected by an aluminum–zinc alloy coating (often abbreviated AZ) can extend service life significantly. The premium is real, but so is the payoff in reduced maintenance and longer intervals between repaints or replacements. Always combine the right alloy or coating with compatible fasteners and sealants to avoid galvanic corrosion.

Finish systems and color matter, too. High-performance fluoropolymer paints hold color and gloss well over time, while more economical coatings can be suitable for less demanding settings. Textured or matte finishes help camouflage minor waviness on broad flat pans, and they can reduce glare in bright sun. When comparing products, ask about metal thickness, coating weight, and expected performance in your climate. Small details—fastener type, seam height, paint chemistry—add up to big differences in real-world durability.

Installation Process of Steel Roofing

Installing steel roofing is as much about planning and detailing as it is about fastening panels. A well-executed job begins long before the first sheet is lifted to the eave.

Pre-construction and assessment:

– Measure roof planes carefully, recording pitch, overhangs, hips, and valleys.

– Inspect the deck for rot, delamination, or unevenness; replace or plane as needed.

– Review local codes for required underlayment, ice barriers, ventilation, and fire ratings.

– Order panels, trims, and accessories (ridge, hip, gable, valley, boots) with a few spares for field adjustments.

Substrate preparation and underlayment:

– Tear off old roofing if required by code or condition; some assemblies allow installation over a single existing layer.

– Install drip edge at eaves and rakes to direct water clear of fascia and fascia-to-soffit transitions.

– Lay a high-quality synthetic underlayment; in cold climates, add a self-adhered ice and water barrier at eaves, valleys, and around penetrations.

– Ensure continuous intake and exhaust ventilation; balanced airflow reduces condensation and heat buildup.

Flashing and layout:

– Pre-fit valley metal, step flashings, and chimney saddles; dry-fit tricky intersections to avoid surprises.

– Snap reference lines so panels stay square; small layout errors compound across wide roofs.

– Stage panels where they can be lifted safely; protect coatings from scratches during handling.

Panel installation and fastening:

– Start at the true square edge; align starter strips or cleats precisely.

– For exposed-fastener panels, drive corrosion-resistant screws perpendicular to the surface, seated snugly without crushing washers; follow specified spacing in ribs or flats as directed.

– For standing seam, engage seams fully and verify clip placement and expansion allowances.

– Use shears or nibblers for cuts; abrasive blades can burn coatings and invite rust.

Penetrations and finishing details:

– Seal pipe and vent penetrations with compatible boots and butyl tape; avoid mixing dissimilar metals.

– Flash skylights with step and head flashings integrated under/over courses as prescribed.

– Install ridge caps with vented closures if using a vented assembly; add snow guards in snowy climates to manage sliding loads.

– Touch up minor scratches promptly with manufacturer-matched paint to protect cut edges.

Quality checks and cleanup:

– Sight along seams for straightness; verify fastener lines are even and properly seated.

– Confirm drainage at valleys and gutters; remove swarf (metal filings) that could rust-stain panels.

– Document the installation with photos for warranty and future maintenance reference.

Timelines vary with crew size and complexity. A simple, single-story roof around 2,000 square feet may take two to four days for an experienced crew, while steep slopes, multiple dormers, and complex flashings add time. Weather matters, too—wind and rain complicate handling and sealing. Patience with layout and flashings pays dividends; most callbacks trace back to rushed intersections, not the open fields of panel.

Conclusion, Costs, and Maintenance Checklist

Choosing steel roofing is a decision to trade a slightly higher upfront investment for decades of predictable performance. Understanding cost ranges and ownership tasks helps set expectations and keeps the roof looking and working the way it should.

Costs and value factors:

– Material-only prices for many residential steel profiles commonly range from roughly $2 to $6 per square foot, depending on thickness, profile complexity, and finish chemistry.

– Installed costs often fall in the vicinity of $6 to $14 per square foot, influenced by roof pitch, story count, regional labor rates, tear-off needs, and the number of hips, valleys, and penetrations.

– Over time, potential energy savings, fewer repairs, and long repaint cycles can soften the lifecycle cost, particularly in hot-summer or wildfire-prone regions.

Maintenance made simple:

– Inspect twice a year and after major storms; clear leaves and branches from valleys and gutters.

– Rinse with a garden hose if dust or pollen accumulates; avoid harsh pressure washing near seams or flashings.

– Check sealants and closures every few years; exposed fastener systems may need periodic retightening or gasket replacement around the 5–10 year mark.

– Touch up nicks promptly and keep dissimilar metals (like copper runoff) away from steel surfaces to prevent staining or galvanic reactions.

Comfort and acoustics are common questions. When installed over solid decking with standard underlayment and attic insulation, steel roofs are generally comparable in sound transmission to other materials during rain. In attic conversions or vaulted ceilings, adding sound-damping underlayment or a ventilated air space can further reduce noise.

Decision checklist to guide your next steps:

– Climate risks: salt air, wildfire exposure, hail, heat, or heavy snow.

– Roof geometry: pitch, complexity, and the number of penetrations.

– Desired look: crisp seams, shingle-like texture, or tile/shake profiles.

– Budget and timing: upfront cost versus lifecycle value and maintenance comfort.

– Code and community rules: local requirements and any neighborhood design standards.

Final word for homeowners, property managers, and builders: steel roofing brings together durability, energy-savvy finishes, and flexible design in a way that fits modern performance goals. If you pick the right profile and coating for your climate, pair it with quality underlayment and meticulous flashings, and keep to a modest maintenance rhythm, you can expect a roof that looks composed and performs steadily across seasons. It is a practical, future-minded choice—one that trades weekend patchwork for quiet confidence every time the weather turns.