Solar Container Foldable Housing: The Future of Sustainable Living

Outline and What You’ll Learn

Housing is changing in real time. Two approaches—solar container homes and foldable homes—are emerging as nimble answers to rising construction costs, climate pressures, and the need for adaptable space. This outline sets the stage for a thorough, practical exploration that avoids hype while highlighting where these formats shine, where they struggle, and how to evaluate them for your needs. Think of it as a field guide: we identify the terrain (technology, costs, and regulations), pack the essentials (metrics and checklists), and then walk the path from concept to move-in. Along the way, you’ll find context, facts, and examples to help you make informed decisions without overpromising outcomes.

Here’s how the article unfolds, and what each section delivers in concrete terms:

– Definitions and use cases: How container and foldable homes differ in structure, logistics, and performance.

– Energy systems: Solar sizing, battery storage, and energy-use baselines by climate and lifestyle.

– Materials and durability: Steel shells, insulated panels, weather seals, and corrosion control.

– Cost frameworks: Acquisition, site work, permits, transport, and long-term operating costs.

– Sustainability metrics: Embodied carbon, Energy Use Intensity, water, and circular-design strategies.

– Risk and resilience: Wind, seismic, fire, and heat resilience, plus maintenance needs.

– Adoption roadmap: Zoning, finance, site assessment, and timelines from order to occupancy.

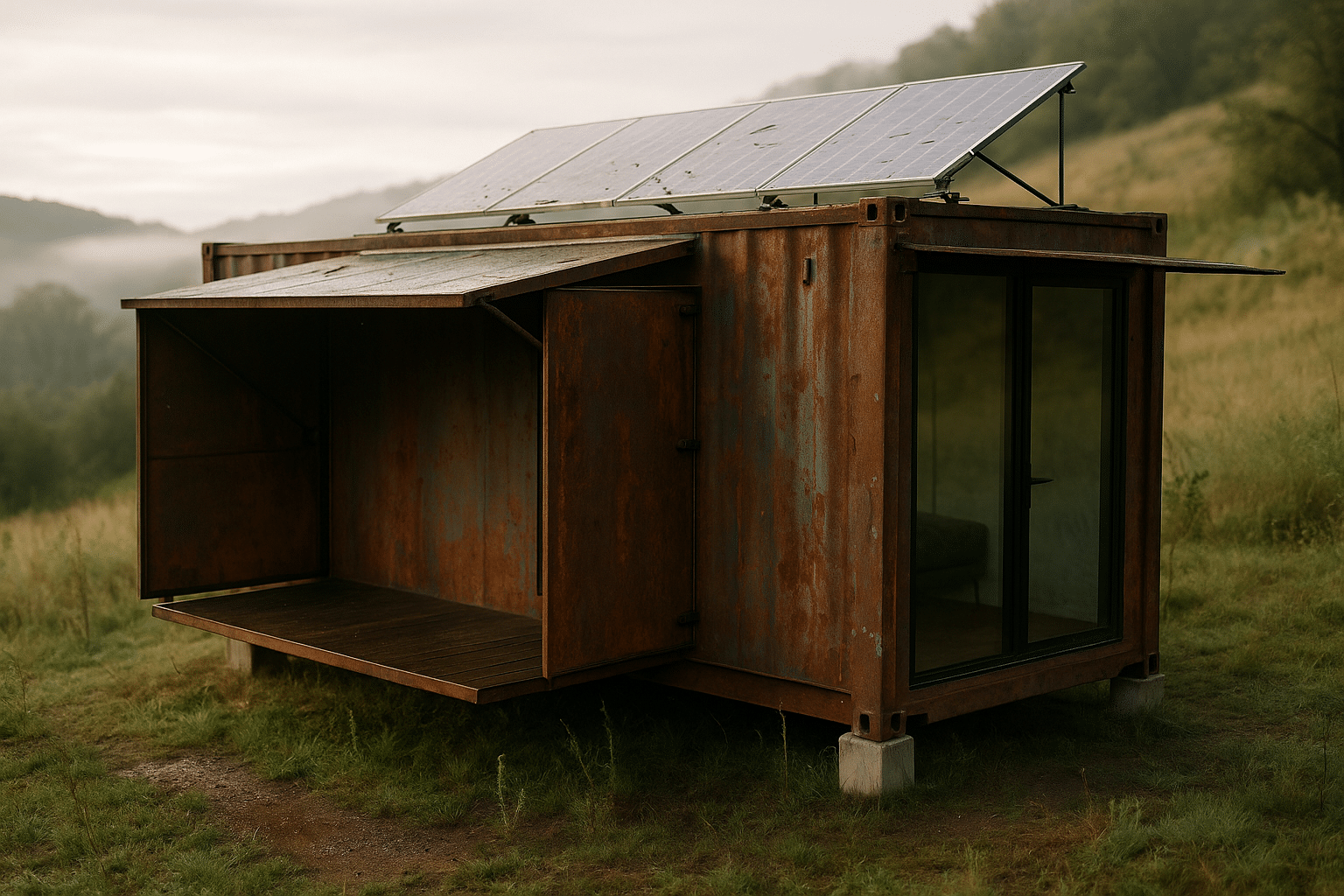

Why this matters now is straightforward. Urban infill sites often demand compact footprints and swift installation, while rural plots benefit from off-grid capability and mobility. Both contexts reward designs that are efficient, movable, and repairable. A 20- or 40-foot steel module can become a durable shell for living or working; a folding unit can arrive compact and open into a generous plan within hours or days. When powered by well-sized solar and supported by thoughtful water and waste strategies, these homes can lower monthly bills and environmental impact. This piece translates those possibilities into concrete steps, including rough numbers and realistic constraints, so you can decide whether these formats fit your goals and budget.

Solar Container Homes: Design, Energy, and Costs

Solar container homes start with a simple proposition: repurpose a steel shipping container into an insulated, code-compliant dwelling and power it with on-site solar. Standard sizes are roughly 20 feet by 8 feet (about 160 square feet) and 40 feet by 8 feet (about 320 square feet), with high-cube variants offering extra interior height. The steel structure is strong, but it needs careful modification: cutting openings for windows and doors requires reinforcing the frame, treating cut edges, and managing thermal bridges. Interior comfort depends on insulation strategies such as rigid boards, mineral wool, or closed-cell spray foam; R-20 to R-30 walls and R-30 to R-40 roofs are common targets for many climates. Ventilation with heat recovery can keep indoor air fresh while reducing energy losses.

Solar planning begins with roof area and orientation. A 40-foot roof can generally host 3–6 kW of photovoltaic panels if obstructions are minimal; ground or pergola-mounted arrays can expand capacity. In a sunny region, 1 kW of PV may generate 4–6 kWh per day, yielding 12–36 kWh daily for 3–6 kW. Efficient, all-electric appliances and LED lighting allow many small homes to operate on 6–15 kWh per day, depending on climate and occupancy. Battery storage in the 10–20 kWh range can cover evening use and short outages, while a modest inverter generator may serve as a backup in prolonged cloudy spells. Real-world performance hinges on shading, panel tilt, and seasonal variation; a shade analysis and a simple energy model are invaluable.

Costs vary with scope and location. Conversions can range from modest builds to high-spec units with premium finishes. A helpful breakdown looks like this: acquisition and transport of the container, structural modifications, insulation and air-sealing, mechanical systems (heating/cooling, ventilation), electrical and plumbing, interior fit-out, and on-site work (foundation piers, utility connections, or off-grid systems). Per-square-foot costs can land around the lower end for basic finishes and rise substantially with custom glazing, smart controls, or advanced cladding. Operating costs, however, may be quite manageable when solar offsets most electricity needs. Maintenance includes corrosion control—periodic inspection of paint, fasteners, and roof penetrations—and standard building upkeep. When executed with care, solar container homes can offer sturdy shells, compact footprints, and predictable energy profiles, especially in sunny climates and sites with minimal shading.

Where do container homes excel compared with conventional tiny homes? Logistics and durability stand out. The intermodal format ships easily by truck or rail, stacking and anchoring securely. Steel resists pests and can be engineered to meet strict wind and seismic requirements. Potential trade-offs include thermal bridging if details are sloppy, the need for soundproofing, and the reality that interior widths are limited unless multiple modules are joined. Thoughtful design—insulated chases, continuous exterior insulation, and high-performance windows—can address these concerns while preserving the structural advantages of the steel shell.

Foldable Homes: Speed, Flexibility, and Performance

Foldable homes arrive compact and expand on-site, trading storage volume during transport for extra floor area after deployment. Many use a steel or aluminum chassis with hinged walls and roofs, plus structural insulated panels that lock into place. The promise is speed: a small crew, a crane or forklift, and a day or two can transform a flat pack into a weather-tight shell. This agility suits remote sites, post-disaster recovery, and infill lots where street closures or staging areas are limited. The trick is ensuring that speed does not compromise durability, thermal performance, or the integrity of weather seals over many cycles of folding and unfolding.

From an engineering standpoint, hinges, gaskets, and latches are the stars. Repeated motion requires robust hardware and replaceable seals to maintain air- and water-tightness. Thermal bridging is addressed with insulated splines, careful gasket placement, and continuous exterior insulation where feasible. R-values comparable to well-built traditional homes (e.g., R-20 to R-30 walls, R-30 to R-40 roofs) are achievable with today’s panel systems. Mechanical systems lean all-electric: compact heat pumps, heat-pump water heaters, and balanced ventilation with filtration. Electrical design anticipates both grid and off-grid operation, with roof-integrated or adjacent solar arrays and battery packs sized to demand.

Costs depend on finish levels and site complexity. Foldable homes can benefit from factory-controlled quality, which may reduce waste and compress timelines. Site work—footings or screw piles, anchoring, drainage, and final utility connections—remains a meaningful share of the budget. Transport is often simpler than moving a wide-load module because the unit ships in a smaller footprint. Per-square-foot costs can be competitive with container conversions, particularly when interior volume expands significantly after unfolding. Lifespan considerations focus on moving parts: plan for periodic inspection and replacement of weather seals, touch-up of protective coatings, and hinge lubrication. With a basic maintenance routine, these homes can hold up well, especially when protected from standing water and directed exposure to harsh winds.

How do foldable homes compare to containers? Advantages include rapid installation, larger unfolded interiors without combining multiple modules, and the potential for lower transport costs. Considerations include more complex moving assemblies, a reliance on perfectly executed seals, and the need for clear instructions for re-folding if relocation is planned. In climates with heavy snow or high wind exposure, structural engineering and anchoring details are critical. When paired with solar, foldable roofs can host 3–5 kW arrays on modest footprints, and ground mounts can scale further. The result is a flexible platform: quick to deploy, straightforward to power, and adaptable for seasonal or permanent use.

Sustainability Metrics: From Embodied Carbon to Everyday Use

Sustainability is more than a label; it is a set of measurable outcomes across the building’s life cycle. Start with embodied carbon—the emissions associated with materials and manufacturing. A standard steel container weighs several thousand kilograms, and steel production carries significant carbon intensity. Upcycling a container avoids the emissions of newly fabricated framing but still requires insulation, finishes, and sometimes substantial reinforcement. Foldable homes typically rely on metal frames and insulated panels; their embodied impact varies with panel cores, facings, and the proportion of recycled content. A basic rule of thumb: prioritize durable, low-carbon materials where possible and design for repair rather than replacement.

Operational energy drives long-term impact. A small, well-insulated, all-electric unit in a mild climate can target an annual Energy Use Intensity around 20–35 kBtu/ft²-year (roughly 63–110 kWh/m²-year), depending on occupancy and ventilation rates. In colder climates, careful air-sealing, right-sized heat pumps, and high-performance windows reduce loads substantially. Solar sizing follows demand: for many small homes, a 3–6 kW array can cover typical daily use if occupants practice sensible energy habits. Storage in the 10–20 kWh range adds resilience; a demand-response strategy—running laundry and hot water heating during sunny hours—improves self-consumption and lowers strain on batteries.

Water and waste matter just as much. Low-flow fixtures can drop indoor water use below 40–50 gallons per person per day, and greywater irrigation (where allowed) reduces potable demand on landscapes. Compact, high-efficiency filtration and rain harvesting (for non-potable uses) help in drought-prone regions. Material choices should consider end-of-life: mechanical fasteners that allow disassembly, recyclable metals, and panels with documented take-back pathways advance circularity. Keep an eye on refrigerants in heat pumps; lower global warming potential alternatives reduce climate risk over the equipment’s life.

To make sustainability tangible, use a simple scorecard during design and procurement:

– Embodied carbon: kg CO₂e per square meter of floor area, with material Environmental Product Declarations where available.

– Energy: modeled annual kWh and peak loads, with sensitivity to climate and occupancy.

– Water: indoor gallons per person per day and outdoor sources like rain or recycled water.

– Indoor air quality: ventilation rates, filtration levels, and materials with low emissions.

– Durability: expected replacement intervals for seals, coatings, and mechanical systems.

– Adaptability: ease of relocation or reconfiguration without major waste.

Finally, resilience bridges sustainability and safety. Consider risk scenarios—heat waves, smoke events, grid outages, and storms—and plan accordingly. Passive measures like shading, insulation, and cross-ventilation reduce reliance on active systems. Battery-backed solar covers short outages; a small backup generator can be reserved for extended low-sun periods if local rules permit. Anchoring strategies, corrosion protection, and fire-aware landscaping further harden the home against extreme conditions. These steps turn sustainable intent into reliable performance over decades, not just in the first season.

Roadmap and Conclusion: Choosing What Fits Your Life

Choosing between a solar container home and a foldable home is not about chasing trends; it is about aligning a home’s capabilities with your goals, site, and budget. Start with the site. Map sun paths and shade, note prevailing winds, and document access for trucks or cranes. Check zoning, minimum dwelling sizes, setback rules, and whether movable or modular units require special permits. If you plan to go off-grid, verify water rights, septic allowances, and fire access. Early calls to local officials can save weeks and reduce redesign risk.

Next, right-size energy. Tally typical loads—heating, cooling, cooking, hot water, lighting, and plug devices. A compact all-electric home might use 6–15 kWh per day in a mild climate, more in harsh winters. Size solar arrays to cover average daily use with seasonal flexibility, and consider adding 10–20 kWh of battery storage to bridge evenings and short outages. If budgets are tight, prioritize insulation, air-sealing, and efficient appliances before expanding generation; reducing demand is almost always the most cost-effective first step.

Budget with a full picture. A container conversion can vary widely depending on the level of customization; foldable homes can be cost-effective when speed and factory precision are priorities. Factor in site work (footings or screw piles), transport, craning, permitting, utility fees, and a contingency of 10–15 percent. Long-term costs include maintenance of coatings and seals, filter changes, and eventual replacement of batteries or HVAC components. Financing options may include local credit unions, green-minded lenders, or construction-to-permanent loans; ask about appraisal methods for modular or movable units and any incentives for solar or high-efficiency equipment available in your region.

Compare formats objectively:

– Solar container homes: durable shells, straightforward logistics, strong performance when insulated and detailed well. Narrow interior widths may require modular combinations for larger spaces.

– Foldable homes: rapid deployment, efficient transport footprint, and spacious unfolded plans. Pay attention to the quality and maintainability of hinges, seals, and locking mechanisms.

– Both formats: pair well with solar, benefit from efficient electrified systems, and can meet stringent energy goals with thoughtful design.

Timeline planning keeps projects calm. Design and permitting can take 4–12 weeks depending on jurisdiction; fabrication may run 4–10 weeks; on-site installation ranges from a couple of days to two weeks, followed by inspections and punch-list items. Build a simple risk register—supply chain delays, weather windows for crane day, or utility scheduling—and assign backup plans. A small project notebook with checklists for inspections, maintenance intervals, and warranty contacts will pay dividends later.

In closing, if you value agility, measurable sustainability, and lower operating costs, both solar container and foldable homes deserve a close look. Visit local examples, ask for performance data, and request clear drawings that show insulation, air barriers, and flashing details. Choose the format that matches your site constraints and lifestyle, not the loudest marketing claim. With grounded planning and a few smart choices—right-sized solar, robust envelopes, and simple, serviceable systems—you can create a home that works as hard as you do, day after day, season after season.