Your Complete Guide to Prefab Container Storage

Introduction and Outline

Across neighborhoods, farms, and small businesses, containers are quietly transforming into dependable storage rooms and even hard-working garages. The appeal is simple: strong weather-resistant steel, fast setup, and modular flexibility that grows with your needs. Whether you’re sheltering a classic motorcycle, organizing tools, or creating overflow space for inventory, container-based solutions deliver a practical blend of durability and value. Consider this guide your roadmap—from picking a configuration to understanding the dollars and permits behind the project.

Outline of what you’ll learn:

– Container Garage: layouts that fit real vehicles and gear, structural considerations, and comfort upgrades

– Prefab Container: how factory-built modules differ from repurposed boxes, plus insulation, utilities, and code topics

– Container Price: transparent cost ranges for units, delivery, site prep, and modifications

– Planning & Compliance: permits, foundations, climate considerations, and maintenance routines

– Conclusion & Checklist: step-by-step actions to turn ideas into a safe, long-lived installation

Why containers? Standardized steel boxes are designed to endure global freight routes—salt air, rough handling, and stacked loads—so a stationary life in a backyard or yard feels easy by comparison. Their corrugations act like the ribcage of a whale, stiff and purposeful, and their corner castings accept twist-locks or plates for secure anchoring. On the sustainability side, reusing a retired unit repurposes several thousand pounds of steel while minimizing the need for new building materials. For speed, a container can be delivered and set in hours, not weeks. Still, performance hinges on thoughtful choices: local codes, site drainage, ventilation to curb condensation, and correct anchoring for wind or seismic demands.

Who benefits most? Homeowners seeking secure storage with a compact footprint; tradespeople who need a lockable workshop; small retailers tackling seasonal inventory; and hobbyists who want a weather-tight shell that can be improved over time. In the pages ahead, you’ll see key dimensions (interior height, door openings), practical modification ideas (roll-up doors, ramps, windows), and price factors (unit condition, transport distance, foundation type). The result is a grounded, stepwise view—so you can spend once, install confidently, and enjoy storage that works hard without fuss.

Container Garage: Layouts, Materials, and Performance

Turning a container into a garage starts with sizing. A standard 20-foot unit offers roughly 160 square feet of floor area, while a 40-foot unit doubles that to about 320 square feet. Interior width commonly measures about 7 feet 8 inches, with an interior height near 7 feet 10 inches for standard units and around 8 feet 10 inches for high-cube models. Door openings are typically near 7 feet 8 inches wide; height hovers around 7 feet 5 inches on a standard container, slightly more on a high-cube. These clearances matter: a compact car or motorcycle fits comfortably; a full-size SUV may need a high-cube or modified opening; and side access via a personnel door can speed daily use.

Popular garage layouts include:

– Single 40-foot: ample space for one vehicle plus shelving, or two motorcycles with a workbench

– Two 20-foot units with a gable or shed roof between: yields a covered bay while retaining dual lockable rooms

– Two 40-foot units with a structural truss span: creates a wide central drive-through bay with enclosed storage on both sides

Materials inside the box deserve attention. Factory floors are commonly 1-inch-plus marine-grade plywood, strong enough for heavy loads and treated for durability. For vehicles, many owners add spill-proof floor mats or an epoxy-style coating to protect the wood and simplify cleanup. Ventilation is essential: containers often include small passive vents, but adding louvered vents or a roof turbine reduces condensation. In humid or variable climates, insulation helps control temperature swings; closed-cell spray foam, for instance, delivers a high R-value per inch and doubles as a vapor barrier on steel walls.

Security and comfort upgrades add real utility:

– Roll-up or sectional door insert for smoother daily access

– Personnel door with reinforced frame for quick entry without unfolding cargo doors

– LED-ready wiring runs in conduit, with exterior-rated fittings

– Ramps or flush thresholds to prevent a “lip” from snagging bumpers

Anchoring is non-negotiable in windy or seismic zones. Corner castings can be secured to concrete piers or a slab; ground screws and helical piles are common alternatives for minimal excavation. Weight offers an advantage: a typical 20-foot container weighs roughly 4,800–5,200 lb empty; a 40-foot often ranges around 8,000–8,800 lb. Even so, uplift forces in storms are serious, so mechanical connections matter. Finally, respect the structure when cutting openings: adding frames, headers, and reinforcement preserves rigidity and helps the garage feel solid for years to come.

Prefab Container: What “Prefab” Really Means

“Prefab container” can mean two related but distinct paths. One path repurposes a standard freight container (steel frame and corrugated walls) and modifies it for storage or workspace. The other path uses a factory-built module manufactured to container-like dimensions but engineered from the start for people to occupy, with insulated panels, integrated wiring, and code-ready doors and windows. Both approaches can deliver tidy, efficient storage or light workshop space, but they differ in how quickly they reach code compliance and how easily they accept utilities.

Repurposed freight containers are renowned for their rugged shell. The steel is designed to resist dents and flexing during global transport and stacking. Because they start as airtight boxes, condensation control becomes the key to comfort—expect to plan for vents, insulation, and a moisture strategy. Electrical runs typically sit in conduit along walls or drop from a ceiling chase. Cutouts for windows, fans, or roll-up doors are straightforward when reinforced with tube steel frames or structural angles, keeping the corrugated skin braced against wind and torsion.

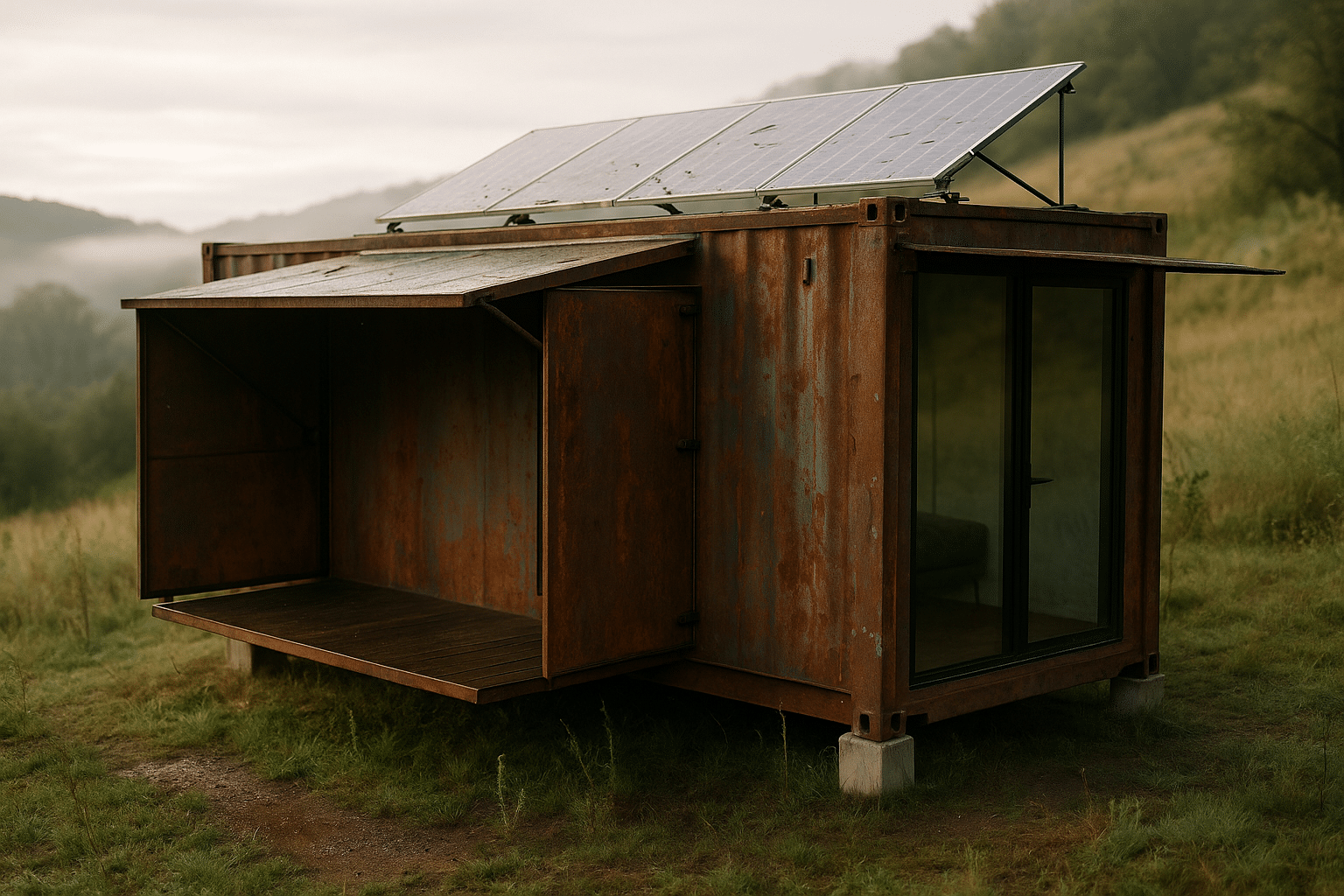

Factory-built prefab modules tilt toward instant usability. Many arrive with insulated sandwich panels (steel skins with foam core), pre-installed outlets, and exterior doors sized for egress. Some offer options like:

– Pre-wired breaker panels, ready for a single exterior feed

– Multi-pane windows with low-e coatings for comfort

– Interior finishes such as washable wall panels and integrated LED lighting

Lead times vary by supplier and region, but prefab modules can often ship within weeks after order finalization, while custom modifications on repurposed containers depend on the complexity of cutouts, finishes, and local fabricator capacity. Foundations are similar in both cases—piers, slab, or helical piles—but prefabs may include leveling frames that simplify setup. For compliance, always verify local building codes: storage-only placements are often simpler; adding conditioned space, plumbing, or habitable use triggers stricter rules. In summary, repurposed containers emphasize shell strength and budget control; prefab modules emphasize speed, polish, and a smoother path to plug-and-play functionality.

Container Price: From Unit Cost to Turnkey Budget

Pricing is where clarity saves money. Start with the container itself. In many regions, a used “wind and water tight” 20-foot unit might land in the neighborhood of 1,200–2,500 USD, while a newer “one-trip” 20-foot often runs around 2,200–4,000 USD. For 40-foot units, used examples commonly range 1,800–3,500 USD, with one-trip models around 3,600–6,000 USD. High-cube versions typically command a modest premium due to the extra vertical space. Local supply, port proximity, and market swings can nudge these numbers higher or lower.

Delivery deserves its own line item:

– Local haul fees frequently include a base rate plus a per-mile charge; 4–8 USD per mile is common in some areas

– Site access affects cost; tight turns or soft ground can require specialized trucks

– Offloading may be included with tilt-bed delivery; cranes or forklifts add 300–800 USD where needed

Site preparation and foundations have wide ranges. A compacted gravel pad is economical and often sufficient for non-habitable storage, while a full concrete slab can run about 6–10 USD per square foot depending on thickness, rebar, and local labor. Helical piles or ground screws are a popular mid-range solution, minimizing excavation while providing robust anchorage. If you plan to add a roof between two containers, budget for structural steel, purlins, and metal roofing—costs vary with span and snow/wind ratings.

Modifications and comfort upgrades add precision to the budget:

– Roll-up door insert: roughly 600–1,500 USD depending on size and framing

– Personnel door with security frame: about 350–900 USD

– Window with bar grate or shutter: commonly 250–700 USD

– Spray foam insulation (closed-cell): around 1.50–3.00 USD per square foot of surface area

– Electrical rough-in (basic circuits and lighting): 800–2,000 USD for simple setups

Permits and inspections vary by jurisdiction—expect anything from 100 USD for a simple zoning permit to 1,000 USD or more for engineered drawings in stricter regions. When you combine unit, delivery, foundation, and modest upgrades, many owners see all-in budgets such as:

– 20-foot storage-only install: roughly 4,000–9,000 USD

– 40-foot garage conversion with basic insulation and power: roughly 9,000–18,000 USD

For context, cost per square foot can compare favorably with small stick-built or metal outbuildings, especially when factoring speed of deployment. Still, every site is unique. Soil conditions, weather exposure, and access constraints can tip the scales, so build a line-item estimate and add a 10–15% contingency for surprises.

Conclusion and Practical Checklist

Turning a container into storage or a garage is less about chasing trends and more about matching a tough steel shell to your real needs. The path is refreshingly direct: choose the right size, plan the access points, anchor it correctly, and manage moisture. Do those well, and the result will feel like a vault that opens as easily as a toolbox—reliable, tidy, and ready whenever you are. To help you move from idea to installed, here’s a concise checklist shaped by field-tested practices.

Site and compliance:

– Confirm zoning; note setbacks, height limits, and HOA rules if applicable

– Check whether your use is “storage only” or “habitable”; requirements differ

– Ask about wind, seismic, and snow load criteria; request engineering where needed

Foundation and placement:

– Pick a level, well-drained spot; avoid pooling water

– Choose piers, a slab, or helical piles; ensure mechanical connections at corner castings

– Plan truck access: turning radius, overhead lines, and soil bearing strength

Layout and modifications:

– Decide on door strategy: keep cargo doors, add a roll-up, or include a personnel door

– Map shelving and work zones to ensure the vehicle can still move easily

– Reinforce any wall or roof cutouts with proper framing to preserve structural rigidity

Comfort, safety, and longevity:

– Control condensation with vents and, in variable climates, insulation and a vapor barrier

– Use corrosion protection: clean, prime, and paint; seal penetrations promptly

– Add lighting, GFCI-protected outlets where required, and exterior-rated fixtures

– Protect floors with mats or coatings; inspect and re-seal fasteners annually

Budget and logistics:

– Price the unit, delivery, foundation, and modifications separately to avoid surprises

– Ask for photos of the exact container, inside and out, to verify condition

– Build a 10–15% contingency to cover crane time, grading, or material price changes

If you’re a homeowner seeking clutter-free storage, a tradesperson wanting a secure workshop, or a small operator managing inventory swings, container-based solutions offer a disciplined, stepwise way to gain square footage without prolonged construction. Start small with a single unit, or pair boxes with a roof to create a roomy bay; either way, lean on local codes, sound anchoring, and sensible moisture control. Do that, and your container won’t just store things—it will quietly simplify your days for years to come.